CFST 6508 compliance explained: 10-step MSST method for French-Swiss companies

27/07/2025

Roles of the occupational physician and safety specialist in the MSST

14/09/2025Table of contents

<.nav>- Panorama 2025: Who does what in occupational safety in Switzerland (overview)

- MSST: When and why to call in specialists (CFST obligations 6508)

- SECO and federal labour inspectorate: national coordination and enforcement supervision

- CFST/EKAS: Directives, standards and practical tools for companies

- Suva: laa implementing body for risk sectors (who is affected?)

- Cantonal labour inspectorates: missions, scope and local specificities

- Who does what : comparative table of players (download)

- Scenarios concrets-pour les PME : examples of compliance by sector

- Mechanics and bodywork workshop: risks, typical controls, MSST action plan in 90 days

- Office and services (banking, IT, insurance) : psychosocial risks, ergonomics, teleworking

- Care and medico-social : patient handling, injections, biosafety, on-call duty

- Commerce and logistics: handling, trolleys, docks, evacuation plan and drills

- Documents and evidence to keep ready for any control (check-list)

- Sst policy, responsibility chart and safety committee minutes

- Risk assessment: method, hazard register and action plan

- Training and accreditation: registers, certificates and retraining

- Instructions, operating procedures, chemical product sheets, accident and incident register

- Msst traceability : management reviews, indicators, internal audits and action monitoring

- Stage 1: initial audit and prioritisation of major risks

- Step 2: MSST team designation and resource planning

- Step 3: 90-day action plan (quick wins + medium-term projects)

- Step 4: Train, document, measure and continuously improve

- Frequently asked questions about occupational safety players in Switzerland (FAQ)

- Suva or cantonal inspection: who controls my service company?

- Does CFST Directive 6508 apply to micro-businesses?

- Can I outsource the MSST function completely?

- What does an SME risk in the event of non-compliance during an inspection?

- How long should MSST evidence and inspection reports be kept?

- How can you find out quickly whether your company is more relevant to Suva or the cantonal inspection?

- How to prepare for an inspection in less than two weeks?

Panorama 2025: who does what in occupational safety in Switzerland (overview)

Occupational safety in Switzerland is based on an ecosystem of complementary players: SECO / Federal Labour Inspectorate, CFST/EKAS, Suva and the cantonal inspectorates. Understanding who does what avoids duplication, speeds up MSST compliance and improves your preparation for inspections. In a nutshell:

- SECO coordinates and monitors the implementation (federal level) of the LTr and, outside the scope of Suva, the LAA.

- CFST/EKAS issues the directives (including 6508/MSST) and clarifies the organisation of enforcement.

- Suva carries out the LAA in companies with special hazards (OPA list art. 49) and inspects certain work equipment; elsewhere, responsibility lies with the cantonal inspectorates.

- The obligation to provide accident insurance (LAA) and health protection (LTr) apply to the vast majority of companies and employees.

For practical implementation (teams, prioritisation, evidence), see our page on occupational safety and healthl (OSH).

Aims of the guide: understanding roles and avoiding confusion between Suva and cantonal inspectorates

This guide serves as an operational compass for executives, HR, HSE and operations managers who have some very practical questions:

- Who inspects me? If you are in a branch where prevention requires special knowledge (art. 49 OPA) (e.g. construction, special work, high-risk equipment), Suva is competent; in other cases, it is generally the cantonal inspections (under SECO supervision).

- What does each player check? Suva and the inspectorates examine the prevention of occupational accidents/illnesses, risk control, equipment, documentation and training; the SECO ensures uniformity of implementation.

- What do I have to prove? The directive CFST 6508 requires a proportionate MSST system (hazard assessment, plan of measures, training, monitoring) to demonstrate that the employer is fulfilling its duties.

The key: zero grey areas between Suva, the canton and SECO, a MSST sized to your risks, and controls that go smoothly.

Legal framework in brief: LTr, LAA, OPA and CFST directive 6508 (MSST)

Directive CFST 6508 (MSST): operationalises the obligation to use occupational physicians and safety specialists; it does not change the scope of the OPA but describes how to organise your MSST system (thresholds, roles, tasks, evidence).

LTr – Labour Law: basis for health protection, ergonomics, working hours and working conditions; basis for cantonal controls under SECO coordination.

LAA – Accident Insurance Act: compulsory insurance for employees against accidents and occupational illnesses; anchors prevention and employer duties (art. 82).

OPA – Ordinance on the Prevention of Occupational Accidents and Diseases: specifies the organisation of enforcement (art. 47-50), distributes competences (including the list of sectors/equipment with Suva competence in art. 49) and sets cross-cutting requirements.

MSST: when and why call in specialists (CFST obligations 6508)

The use of occupational safety specialists and occupational physicians is not a “comfort” option: it is the backbone of a credible MSST system. It becomes obligatory as soon as the company is exposed to special hazards or when in-house skills are insufficient to guarantee effective prevention. This applies both to industry and construction and to services subject to specific risks (electricity, chemicals, handling, machinery, working at height, ATEX environment, night shifts, psychosocial risks, etc.).

In practical terms, a structured hazard assessment must determine whether the company can manage on its own, or whether it needs to call in external experts to design, implement and audit prevention measures.

Practical guide: setting up an MSST >

MSST obligations for SMEs: thresholds, risks and employer responsibilities

The employer remains responsible for the result: protecting the health and safety of employees, demonstrating control of risks and maintaining activity over time. The MSST Directive specifies that the company must be able to prove that it has put in place an organisation proportionate to its risks. In practice, this translates into:

- Assessing hazards: mapping hazardous situations (operations, workstations, products, facilities, third-party interventions), estimating probability and severity, prioritising.

- Plan and document: define OHS objectives, a plan of measures (technical, organisational, human), responsible persons and timelines.

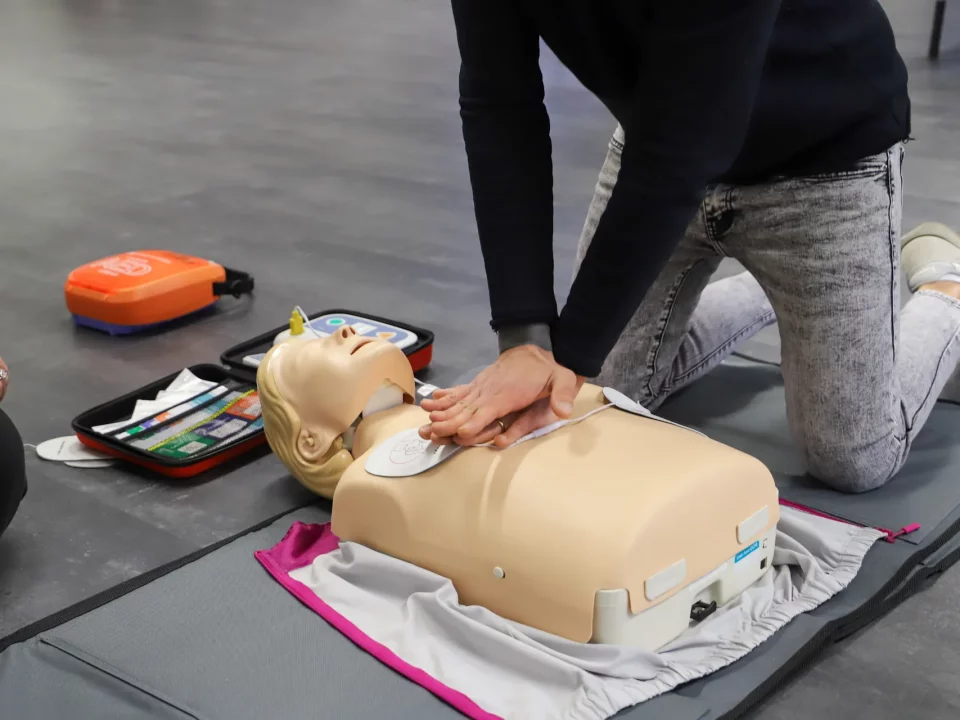

- Train and empower: ensure that each person has the required skills (consignment/LOTO, BLS-AED-SRC first aid, fire/evacuation, PPE, critical procedures), and keep the training tests up to date.

- Implement instructions and operating procedures: clear, accessible, adapted to the field, including for non-routine or outsourced activities.

- Monitoring and improving: tracking indicators (accidents, near misses, audits, overdue actions), conducting management reviews, correcting, capitalising.

- Bring in specialists as soon as necessary: high hazard, major change (new line, new process, new products), multi-site, or recurring low signal (repeated incidents, non-conformities, MSD, RPS).

Quick diagnosis tip: if at least one of these signals is true – serious risk not fully under control, proven lack of in-house skills, regular exposure to unusual or complex operations – get an MSST specialist and/or an occupational physician involved without delay.

MSST team: occupational safety specialist, occupational physician, health protection specialist

An effective MSST team is pluridisciplinary and sized to the reality on the ground :

- Specialist in safety at work (STPS): risk analysis, technical and organisational compliance, action plans, audits, support for improvement projects (machinery, ergonomics, handling, chemicals, ATEX, consignment, work permits, etc.).

- Occupational physician/health protection: medical surveillance, prevention of occupational illnesses, health monitoring in relation to exposure, advice on fitness for the job, prevention of MSDs and psychosocial risks.

- Internal referent (HSE/HR/Management): steers implementation, arbitrates priorities, monitors indicators, animates safety (briefs, talks, feedback).

- Field network (team leaders, operators, maintenance, QSE): enforces instructions, reports weak signals, takes part in incident analyses.

The role of the specialists is not to “take the place” of the company, but to transfer the method: equip, train, create prevention routines, then let autonomy grow, while ensuring a periodic expert eye.

Link to action: MSST audit and compliance plan

To move from “theory” to measurable results, structure your approach into three concrete deliverables:

- MSST audit

- Document review: policy, responsibility chart, hazard assessment, prevention plans, training register, instructions, accident/occurrence register.

- Site visit: observation of workstations, machines, traffic flows, storage, maintenance operations, PPE, lockout, signs, first-aid kits, evacuation plans, fire extinguishers.

- Targeted interviews: management, supervisors, employee representatives, maintenance, critical subcontractors.

- “Major risks/critical gaps/opportunities” summary and pre-prioritisation.

- Roadmap 90 days

- Quick wins (high impact, rapid implementation): simple material corrections, clarification of instructions, missing posters, PPE renewal, refresher training on key actions (fire, first aid, consignment).

- Structuring projects: upgrading of hazard assessment, standardisation of operating procedures, MSD/PWH prevention programme, making work safer (fire permits, consignment, consignees).

- Governance: monthly rituals, dashboard, people in charge, deadlines, success criteria.

- Compliance and rising maturity

- Gradual roll-out to priority sites/teams, training of internal relays, follow-up audits.

- Integration of OHS KPIs into operational performance (frequency, severity, action closure rate, training coverage rate, near miss escalation rate).

- Management review quarterly and adjustments.

SECO and the Federal Labour Inspectorate: national coordination and supervision of implementation

SECO, via the Federal Labour Inspectorate, plays the role of conductor of enforcement in Switzerland. Its mission: harmonise practices between cantons, ensure legal consistency and steer federal inspections in areas that fall within the Confederation’s remit. In practical terms, SECO sets national priorities (campaigns, inspection topics), publishes guidelines for interpreting regulations, coordinates the networks of cantonal inspectorates and works with Suva to avoid overlaps.

For a company, this means a clear frame of reference: the same minimum requirements throughout Switzerland, the same documentary expectations, and an increase in inspectors’ skills thanks to a common doctrine.

SECO’s role in occupational safety: missions, areas covered, interaction with cantons and Suva

- Coordination and harmonisation: SECO ensures the uniform application of occupational health and safety rules, particularly on cross-cutting issues (hazard assessment, MSST organisation, ergonomics, working hours and night work, young workers, maternity, psychosocial risks).

- Monitoring and steering: it plans national campaigns (by theme or sector), monitors implementation indicators and publishes recommendations to correct any discrepancies noted.

- Targeted federal inspections: the Federal Labour Inspectorate conducts inspections in areas under federal jurisdiction and acts as a reference when questions of interpretation arise.

- Interface with cantons and Suva: coordination meetings, shared doctrine, feedback (serious accidents, high-profile incidents), clarification of responsibilities between cantonal inspectorates and Suva depending on the nature of the risks and activities.

- Methodological support: distribution of guides, check-lists and tools to help companies and inspectors assess risks and document prevention measures.

When SECO takes practical action: case examples, thematic audits and recommendations

- National campaigns: for example, one year focused on handling and MSD, another on machine safety, night work or prevention of hazardous substances. Targeted companies are informed of the preferred topics and may be audited on these aspects.

- Controls within the federal perimeter: scheduled or unannounced inspections, often themed, with interviews, visits to workstations, verification of documentary samples and structured reporting (findings, requirements, deadlines).

- Clarification of interpretation: when a canton and a company differ on the scope of a requirement, SECO can clarify the reading to be adopted in order to align practice at national level.

- Post-event feedback: following a major accident or recurring incident, SECO can publish sector-specific recommendations to generalise learning and avoid the repetition of risky scenarios.

Documents expected during a federal inspection: policies, hazard assessment, action plans, etc.

During a federally-led inspection, the expectations are clear and comparable from site to site. Prepare in advance a compliance file structured around four pillars:

- Governance and responsibilities

- Formalised and communicated health and safety policy.

- Roles and responsibilities (management, MSST coordinator, external specialists, supervisors, field representatives).

- Minutes of safety committees, leadership rituals (briefs, talks, feedback).

- Risk management

- Updated hazard assessment (method, results, priorities).

- Dated action plans with responsibilities, deadlines and progress status.

- Technical files: machine and equipment conformity, consignment/LOTO, work permits, preventive maintenance, periodic inspections.

- Skills, information and training

- Training and clearance registers (fire, first aid, BLS-AED-SRC, PPE, critical operations).

- Up-to-date, accessible instructions and operating procedures, incorporating non-routine activities and third-party interventions.

- Induction and retraining systems (new entrants, subcontractors, risk positions).

- Monitoring, surveillance and continuous improvement

- Key indicators (accidents, near misses, action completion rates, training coverage, audits).

- Event log, incident analysis and corrective measures.

- Periodic management review, improvement plan, internal communication.

CFST/EKAS: directives, standards and practical tools for companies

The CFST/EKAS acts as a compass for enforcement in Switzerland: it issues directives, harmonises interpretation and makes available concrete tools to help companies prove that they have their risks under control. For an SME, the interest is twofold: knowing what to put in place and how to document it to move from intention to operational compliance.

CFST Directive 6508 explained simply: objectives, scope, evidence to be kept

Directive 6508 formalises the call for occupational physicians and safety specialists and describes how to organise a proportionate MSST system. In practice, it calls for:

- Assess hazards in a structured way (work situations, processes, products, non-routine interventions, third parties involved).

- Assign clear responsibilities (management, MSST referent, external specialists, supervisory staff, field relays).

- Plan technical, organisational and human measures, with timelines and responsible parties.

- Train and empower exposed employees (first aid, fire/evacuation, PPE, consignment, handling, working at height, chemicals).

- Monitor and improve via indicators, internal audits, incident analyses and management reviews.

- Keep evidence: hazard assessments, action plans, training/clearance registers, job sheets, operating procedures, audit reports, dashboard.

Key message: the 6508 does not add endless obligations; it operationalises prevention so that it is traceable, measurable and verifiable.

CFST/EKAS tools you need to know: checklists, model procedures, compulsory displays

CFST/EKAS offers an arsenal of ready-to-use tools. Useful selection for SMEs:

- Hazard assessment checklist: framework for mapping, weighting and prioritising risks.

- Action plan templates: actions-responsible parties-timeline-status table to monitor and prove progress.

- Machine safety: checklists incorporating protection, consignment/LOTO, compliance upgrades, periodic checks.

- Handling and ergonomics: MSD grids for repetitive workstations, adjustments, aids, gesture and posture training.

- Chemistry/hazardous agents: inventory of substances, use of SDSs, labelling, storage, ventilation, associated PPE.

- Working at height and work permits: standardised procedures, prior checks, guardrails/scaffolding/anchoring, emergency plan.

- Screen work, teleworking, RPS: practical guides for screen work, adjustments, mental workload, alert and listening devices.

- Essential displays: emergency instructions, evacuation, useful numbers, PPE rules, warning procedures.

How to use it effectively:

- Start with an express diagnostic with 3-5 core business checklists.

- Convert variances into a prioritised action plan (90 days).

- Introduce a monthly ritual: progress update, incidents, new risks.

- Centralise the tests in a single MSST file (paper or digital).

- Review checklists for each change (machine, process, organisation, products).

Suva: laa implementing body for high-risk sectors (who is affected?)

Suva is the key player for companies exposed to special hazards. It combines a role as accident insurer, prevention and enforcement: it checks, advises, publishes requirements and monitors their implementation. In practical terms, it works primarily in sectors and operations with a high level of risk (construction, civil engineering, the processing industry, wood and metalworking, industrial maintenance, electrical work, waste management, energy, working at height, explosive atmospheres, etc.).

The role of suva in occupational safety: prevention, control, advice and training

- Preventing and managing major risks: machines and installations, temporary work at height, electricity, load handling, chemicals, ATEX, internal traffic and man-machine interfaces.

- Control and demand: site visits, document reviews, equipment checks, assessment of measures in place, formulation of requirements with deadlines and expected proof.

- Advice and tools: technical recommendations, checklists, sector-specific guides, feedback from incidents, good consignment practices (LOTO), consignees and work permits.

- Training and raising awareness: targeted training programmes (machine safety, height, chemistry, first aid), annual prevention campaigns and themed actions.

Operational objective: measurable and traceable prevention. Suva expects companies to demonstrate systematic control of risks and the permanence of measures (technical, organisational and human).

Suva or cantonal inspection? How do you know who inspects you depending on your activity.

To determine who controls you, start with the nature of your activities and the critical operations carried out on a daily basis:

Typically Suva

- Construction and civil engineering sites (scaffolding, formwork, cranes, lifting).

- Processing industry: wood, metal, plastic, food processing, printing, mechanical workshops.

- Industrial maintenance and interventions on production equipment.

- Electrical work, ATEX interventions, work at height, cutting and presses.

- Management and treatment of waste, deposits and energy sites.

Typically cantonal inspections

- Services and tertiary (banking, insurance, IT, law firms, retail) without high-risk processes.

- Administrations, schools, culture and health excluding technical acts with particular danger.

- Structures focused on working conditions and health protection (working hours, ergonomics, workload).

Mixed / multi-site cases

- A company may come under different skills depending on the site or dominant activity. In practice, this is based on the exposure to risk and the operations actually carried out (production, worksites, maintenance, specialist subcontracting).

- If you outsource “particularly hazardous” operations (e.g. electrical maintenance, work at height), expect requirements aligned with Suva standards, even if your core business is tertiary.

Express diagnosis: if your activity involves machinery, temporary work at height, hazardous energy, hazardous substances or critical non-routine operations, act as if you were within the Suva scope: Formalise your risks, lock in technical controls, document and form.

Suva inspections: frequency, procedure, frequent non-conformities and possible consequences

Frequency

- Depends on risk level, incident history, MSST maturity and situational elements (new line, new process, notable accident).

- Visits can be announced or unannounced; some are themed (machines, height, chemistry…).

A typical visit

- Opening brief: presentation of the site, activities, MSST organisation, sensitive points.

- Document review: hazard assessment, action plan, proof of training/habilitation, critical procedures (LOTO, fire permit/height/confined space entry), accident and inspection records.

- Field tour: observation of workstations, protection, traffic, storage, consignment, PPE, emergency stop devices, displays and instructions.

- Targeted interviews: management, maintenance, operators, subcontractors.

- Debriefing: findings, requirements, deadlines and expected supporting documents (photos, reports, certificates, test reports, training). A follow-up is planned.

Frequently noted non-compliances

- Hazard assessment incomplete or not updated (changes not incorporated, subcontractors forgotten).

- Inadequate machine safety: missing guards, possible bypasses, non-compliant emergency stops, lack of machine risk analyses.

- Consignment/LOTO deficient: procedures absent, staff untrained, padlocks shared, no “zero energy” test.

- Work at height not safe: missing guardrails, uncertified anchors, PPE not checked, non-existent emergency plan.

- Chemistry: inventory and SDS not up to date, storage incompatibilities, insufficient ventilation, lack of operating procedures.

- ATEX: absent zoning, unsuitable equipment, failure to control ignition sources.

- Handling/MSD: no physical load reduction plan, neglected ergonomics, lack of technical aids.

- EPI unsuitable or poorly used: poor choice, maintenance, traceability.

Possible follow-up

- Written requirements with tight deadlines and proofs to be provided.

- Targeted re-inspection to check compliance.

- In the event of grave and imminent danger, immediate stoppage of a machine/operation until sufficient corrections have been made.

- If the requirements are not met, further monitoring and escalation to the relevant authorities.

How to prepare effectively

- Set up a single MSST file: policy, responsibilities, hazard assessment, action plan, training/habilitation records, critical procedures, evidence of checks and tests.

- Prioritise a 90-day plan: equipment quick wins, securing critical operations, targeted retraining (first aid BLS-AED-SRC, fire/evacuation, LOTO, working at height).

- Schedule quarterly internal audits on major topics (machinery, height, chemistry, ATEX) and capitalise on feedback.

Cantonal labour inspectorates: missions, scope and specific local features

The cantonal labour inspectorates are the local point of contact for most companies in French-speaking Switzerland. They monitor health protection, working conditions and accident prevention in companies outside the scope of Suva. Their added value: pragmatic support, rooted in local realities (typology of companies, worksites, urban constraints, multilingualism, cross-border), and an ability to prioritise what matters for day-to-day health and safety.

Labour inspectorate, canton by canton: Vaud, Geneva, Neuchâtel, Fribourg, Valais, Jura (overview)

Each canton organises its inspection according to its size, key sectors and annual priorities. In practice:

- Vaud: high density of industry and construction sites, plus a large service sector. Recurring emphasis on the ergonomics of fixed workstations and the safety of maintenance operations in SMEs.

- Geneva: highly tertiary ecosystem, urban logistics, hotels-restaurants, international institutions. Close monitoring of hours, workload, night work and design of screen workstations.

- Neuchâtel: precision industries, microtechnology, watchmaking. Focus on machine safety, process chemicals and fine ergonomics.

- Fribourg: agri-food, logistics, construction and tertiary sector mix. Cross-functional checks on internal traffic, handling and MSST documentation.

- Valais: construction sites, energy, industry, tourism. Watch out for work at height, climatic conditions (heat/cold), preparedness for emergencies.

- Jura: fabric of industrial and craft SMEs. Frequent topics: machinery, tooling, training new entrants and monitoring near misses.

Good idea: each cantonal inspectorate generally publishes specific recommendations and forms (declarations, exemption requests, campaign themes). Aligning with these local expectations accelerates compliance.

What the cantonal inspectorate checks: working hours, premises, ergonomics, health and safety

Inspectors assess both the organisation and the terrain. Expect an inspection covering in particular:

- Organisation and responsibilities

- Health and safety policy, MSST referent, roles of management and supervisors.

- Existence of an MSST system proportionate to risks, reviews and indicators.

- Working conditions and health protection

- Hours, breaks, night and Sunday work, protection for young people and pregnant women.

- Ergonomics of workstations (screen, office, workshop), prevention of MSD and psychosocial risks.

- Physical environments: noise, lighting, temperature, ventilation.

- Prevention of occupational accidents and diseases

- Updated hazard assessment, technical and organisational measures.

- Safety of machinery and equipment: protection, emergency stops, maintenance, periodic checks.

- Non-routine work: consignment/LOTO, fire permit/height/confined spaces, emergency plan.

- Chemical products: inventory, SDS, storage, labelling, operating procedures and PPE.

- Fire/evacuation: plan, first response resources, signage, drills.

- Subcontracting: safety coordination, reception, clearances, supervision.

- Skills and evidence

- Registers of training and rehabilitation (first aid, BLS-AED-SRC, fire/evacuation, critical operations).

- Instructions visible and understood, operating procedures accessible.

- Record of accidents and near misses, analyses and action taken.

Frequently observed errors: incomplete assessment of hazards, instructions not up to date, insufficient induction training, perfectible consignment, underestimated ergonomics in the tertiary sector, lack of structured follow-up of actions.

Preparing for an inspection visit: registers, posters, instructions, proof of training, etc.

Anticipate the inspection as a demonstration exercise: you need to prove that your organisation protects health and controls risks.

Check-list documentary express

- Health and safety policy, organigram of responsibilities, MSST contact details.

- Updated hazard assessment (scope, method, results, priorities).

- Action plan dated: actions, people responsible, deadlines, status.

- Records: training/qualifications, accidents/near misses, periodic checks (machines, PPE, fire extinguishers, ventilation, lifting).

- Instructions and operating procedures: consignment, work permits, chemicals, emergency response.

- Proof of employee information: welcome, talks, safety brief, posters.

10-point field compliance

- Screen workstations and workshops adjusted (height, supports, lighting).

- Traffic lanes clear, clear signage.

- Machines protected, emergency stops tested, no bypass.

- Hazardous energy: LOTO procedures, individual padlocks, “zero energy” tests.

- Safe storage: loads, chemicals, controlled incompatibilities.

- EPI available, adapted, maintained, traceability checked.

- Updated evacuation plans, accessible fire extinguishers, trained staff.

- Instructions displayed and understood (including non-routine workers and subcontractors).

- Ergonomics covered: adjustments, handling aids, rotations if required.

- Record of events kept, analyses shared and actions tracked.

90-day strategy

- Week 1-2: document review, correction of critical discrepancies, upgrading of displays.

- Week 3-6: making high-risk operations safe (machines, LOTO, heights, chemistry), targeted retraining.

- Week 7-12: themed internal audits, putting actions under control, management review and sustainability plan.

Who does what: comparative table of players (download)

A clear “who does what” comparison helps your teams to quickly identify the right contact, the documentation requirements and the possible follow-up. Integrate this table into a page (HTML) and provide a PDF download for printing in the field and onboarding new recruits.

Comparison Suva / SECO / CFST-EKAS / cantonal inspectorates: missions, bases, sanctions

| Actor | Mission and scope | For whom | Types of checks / interventions | Documents expected at the audit | Possible follow-up |

| Suva | Implementing body for sectors and operations with special hazards; prevention, control, technical requirements and monitoring | Companies exposed to high risks (construction, industry, maintenance, electricity, ATEX, height, etc.) | Site visits (announced or unannounced), themed campaigns, machine/equipment checks, requirements with deadlines | Hazard assessment, action plan, proof of machine conformity, LOTO procedures, record keeping, authorisations, training registers, accident registers, proof of periodic checks. | Written requirements, re-inspection, machine/operation shutdown in the event of serious danger, reinforced monitoring |

| SECO / Federal Inspectorate | National coordination of enforcement; federal controls on dedicated perimeters; harmonisation of practices | Companies falling within the federal scope or cases requiring clarification of interpretation | National campaigns, thematic controls, consistency audits, official recommendations | OHS governance, hazard assessment, action plans, procedural compliance, indicators, management reviews | Alignment recommendations and requirements, compliance deadlines, progress monitoring |

| CFST/EKAS | Issues directives and tools; coordinates and harmonises interpretation for all implementing bodies | All companies and implementing bodies | No direct company “control”: provides guidelines, checklists, guides, models, etc. | Not applicable (methodological framework) | Not applicable (compliance and proof repository) |

| Cantonal inspections | Implementation of health protection and working conditions for the majority of companies outside the Suva perimeter | Tertiary, administration, health, education, commerce, logistics, services… | Scheduled or unannounced inspections, local issues, ergonomics/time/OSH organisation checks | OHS policy, responsibility chart, hazard assessment, action plan, instructions, training records, event records, periodic audits | Written requirements, deadlines, follow-up controls; immediate measures in the event of serious risk |

Good implementation practices:

- Add a colour code (visual tracking of requirements by actor).

- Include a “Who to contact” column with your internal contact points (MSST referent, management, maintenance) to speed up responses to inspectors.

- Offer a Download PDF button on the board, plus a printable version displayed in break rooms and workshops.

Who to contact depending on your situation: industry, construction, health, services, public authorities, etc.

Industry / workshops / maintenance

- Main contact: Suva.

- Priorities: machine safety, consignment/LOTO, height, chemistry/ATEX, enabling training, periodic inspections.

- Prepare: machine risk analyses, compliance plans, intervention procedures, proof of testing and training.

Construction / civil engineering / temporary worksites

- Main contact: Suva.

- Priorities: collective protection, scaffolding, lifting, multi-company coordination, fire permits, emergency plan.

- Prepare: prevention plans, assembly/inspection certificates, safety brief registers, PPE inspections.

Health / medico-social / laboratories

- Main contact: cantonal inspectorate (and specific contacts depending on activity).

- Priorities: patient handling, accidental injections, biosafety, ergonomics, organisation of working hours.

- Prepare: hygiene protocols, workstation sheets, substance inventories, gesture and posture training, incident registers.

Services / tertiary (banking, IT, insurance, retail)

- Main contact: cantonal inspectorate.

- Priorities: screen ergonomics, mental workload, teleworking, organisation of working hours, fire safety/evacuation.

- Prepare: RPS/TMS risk assessment, teleworking charters, evacuation instructions, proof of first aid and fire training.

Administrations / public institutions / education

- Contact: depending on scope, cantonal inspectorate; coordination with SECO for certain areas.

- Priorities: health protection, ergonomic facilities, visitor management, emergency planning, accessibility.

- Prepare: risk assessments for each building/site, evacuation plans, safety maintenance records, proof of staff information.

Hybrid / multi-site cases

- The same company may report to two contacts depending on the activities. Centralise the risk mapping by site, appoint a single MSST referent and keep a record of decisions (who does what, requirements, deadlines, evidence).

Practical scenarios for SMEs: examples of compliance by sector

Let’s move from “who does what” to the field. Here are four typical scenarios, with key risks, expected controls and a 90-day MSST plan to achieve a robust and verifiable level of compliance.

Mechanical workshop and bodywork: risks, typical checks, MSST action plan in 90 days

Key risks

- Machines (housings, emergency stops, interlocks), grinders, presses, lifts.

- Hazardous energies and consignment/LOTO.

- Chemical products (solvents, paints, paint strippers), ventilation.

- Handling and MSD, internal traffic, fire.

What the controller looks at first

- Up-to-date machine risk analyses + proof of compliance.

- Operational LOTO procedures, individual padlocks, “zero energy” test.

- Chemical inventory, data sheets, storage, capture/ventilation, PPE.

- Enabling training (machines, fire/evacuation, first aid), signed registers.

- Evacuation plans, fire extinguishers, signage, regular maintenance of equipment.

90-Day Plan

- Week 1-2: flash audit of machines + chemistry, simple material corrections (casings, labels, signage), safety displays.

- Week 3-6: deployment of LOTO, express team training, updating of chemical inventory and operating procedures.

- Week 7-12: formalised periodic checks (bridges, compressors, electricity), evacuation drills, follow-up internal audit.

Evidence to keep: test reports, before/after photos, training certificates, checklists, maintenance sheets.

Offices and services (banking, IT, insurance): psychosocial risks, ergonomics, teleworking

Key risks

- Ergonomics of screen workstations, musculoskeletal disorders.

- Psychosocial risks: mental workload, deadlines, isolation (teleworking).

- Fire/evacuation, first aid, night work/extended hours.

What the controller looks at first

- Assessment of hazards covering MSD and RPS, associated prevention plan.

- Teleworking charter (working hours, equipment, health and safety guidelines).

- Staff training and information (induction, safety briefing, evacuation drills).

- Accessibility and facilities, lighting, ventilation, noise.

90-Day Plan

- Week 1-2: Ergonomics + RPS diagnosis (short questionnaire + targeted visits), simple material corrective measures (adjustments, supports, seats).

- Week 3-6: updated teleworking charter, “screen workstations” training, active break programme, well-being advisors.

- Week 7-12: evacuation drill, first aid refresher course, introduction of indicators (absenteeism, RPS alerts, minor incidents).

Evidence to keep: assessment reports, workstation plans, information certificates, exercise minutes.

Care and medical-social services: patient handling, injections, biosafety, on-call duty

Key risks

- Handling people, falls, MSD.

- Biological exposure (blood, needles), disinfection products.

- On-call duty, night work, acute stress.

What the controller looks at first

- Hygiene and biosafety protocols: standardised procedures, waste sorting, appropriate containers.

- Training in gestures and postures, technical handling aids, periodic maintenance.

- Traceability of exposure, post-accident procedures, access to emergency equipment.

- Organisation of working hours, breaks, warning systems, workload management.

90-Day Plan

- Week 1-2: review of protocols and critical equipment (DASRI containers, exposure kits), inventory of handling aids.

- Week 3-6: targeted training (handling, biological exposure), simulation exercises, display of procedures.

- Week 7-12: updating of job descriptions, internal health and safety audit, management review of incidents and prevention plans.

Evidence to keep: exposure registers, training certificates, equipment checks, audit reports.

Commerce and logistics: handling, trolleys, docks, evacuation plan and drills

Key risks

- Manual and mechanised handling (pallet trucks, forklift trucks).

- Falls from height/low level, racks, platforms, mixed pedestrian/vehicle traffic.

- Fire/evacuation, product storage (compatibility).

What the controller looks at first

- Hazard assessment covering internal traffic, docks, racking, lifting.

- Authorisation and training of forklift drivers, periodic inspections of forklift trucks and accessories.

- Up-to-date evacuation plan, accessible fire extinguishers, drills carried out.

- Safe storage: loads, stability, chemical compatibility, ventilation.

90-Day Plan

- Week 1-2: marking/separation of flows, visual inspection of racks, traffic plan, posting of instructions.

- Week 3-6: refresher courses for forklift drivers, full inspection of forklifts, securing docks (stoppers, chocks, waistcoats, procedures).

- Week 7-12: evacuation exercise, hazard assessment update, internal traffic/storage audit.

Evidence to keep: driving licences, periodic checks, racking inspection reports, exercise minutes.

Documents and evidence to be kept ready for any inspection (checklist)

A successful inspection is based on a factual demonstration: you must be able to show, in a few minutes, that your organisation protects health and controls its risks. This checklist brings together the MSST compliance tests expected in the majority of situations (Suva or cantonal inspections). The aim: to find each document in less than 30 seconds and prove its recent update.

H&S policy, responsibilities chart and safety committee minutes

- Health and safety policy signed by management, disseminated and understood (objectives, commitments, scope).

- Clear MSST organisation chart: roles, responsibilities and deputies (management, MSST referent, external specialists, management, field relays).

- Assignment letter from the MSST referent and safety relays (scope, resources, reporting).

- Safety committee/HSE meetings: calendar, agenda, VV signed, participants, decisions, actions taken.

- Annual OHS plan: objectives, indicators, campaigns, audits, training, milestones and budget.

Good practice: display the policy and organisation chart, keep the PVs in a unique repository (“MSST_Governance” digital folder) with standardised naming and date of last update.

Risk assessment: method, hazard register and action plan

- Assessment method documented: severity/probability criteria, acceptability levels, prioritisation rules.

- Updated hazard register: hazardous situations, causes, initial/residual risk levels, persons responsible for treatment.

- Structured action plan: technical/organisational/human measures, deadlines, indicators, progress status.

- Specific analyses where relevant: machines, temporary work at height, consignment/LOTO, electricity, ATEX, chemicals, handling, RPS/TMS, confined spaces.

- Traceability of changes: integration of new lines, processes, products, organisations, sites, subcontracting.

- Field evidence: photos, test reports, periodic inspection certificates, inspection checklists.

Good practices: include a summary page “Top 10 major risks/critical deviations/90-day priority actions” to guide the inspector and show control.

Training and authorisations: registers, certificates and refresher courses

- Skills matrix by position/activity (who needs to know how to do what, at what level, with what frequency).

- Training records: fire/evacuation, first aid and BLS-AED-SRC, machine safety, PPE, handling, chemicals, working at height, consignment/LOTO, driving licences.

- Signed certificates by name (trainer, date, duration, programme), proof of recycling at defined frequencies.

for new recruits and subcontractors: booklet, attendance sheet, MCQs if applicable. - Efficiency checks: quizzes, job observations, flash audits (results and remedial plans).

Good practices: a central table “Skills & authorisations” with filters (position, site, expiry date) and recycling alerts.

Instructions, operating procedures, chemical product sheets, accident and incident register

- Updated and accessible instructions and operating procedures: normal and non-routine operations (fire/height permits, confined space entry, lockout, lifting).

- Chemicals: inventory, data sheets, labelling, storage compatibilities, ventilation, associated PPE, accidental spill procedures.

- Fire prevention: updated evacuation plan, first response resources plan, periodic checks, lists of trained team members.

- Accident and near-accident register: declarations, causal analyses, corrective measures, effectiveness monitoring.

- Periodic inspections and checks: machine inspection reports, lifting, electrical installations, scaffolding, fire extinguishers, emergency stop devices.

Good practice: associate each operating procedure with a photo proof of the device in place and the training certificate required to perform it.

MSST traceability: management reviews, indicators, internal audits and action monitoring

- Key indicators tracked monthly: accidents, near misses, action closure rates, training/habilitation coverage, audits completed, critical gaps opened/closed.

- Dashboard by site and consolidated group, with alert thresholds and comments.

- Planned internal audits: reports, non-conformities, action plans, effectiveness checks.

- Periodic management review: decisions, trade-offs, resources, priorities, internal communication.

- Closing tests: post-correction photos, test reports, certificates, re-measurement results.

Good practice: a Kanban of actions (who, what, when, status) visible to management; a Decision log MSST to trace key arbitrations.

Operational objective: with this organised, up-to-date and accessible document base, you reduce inspection time, boost inspectors’ confidence and secure your operations.

Achieving MSST compliance step by step (operational method)

Implementing a solid MSST is not a “paper project”. It’s a pragmatic roadmap, calibrated to your real risks, resources and business objectives. Here’s the method I’m using in 2025 to get measurable results in 90 days, while laying the foundations for long-term performance.

Stage 1: Initial audit and prioritisation of major risks

Objective: to know exactly where you stand and what to treat first.

- Framing: scope (sites, teams, processes), business challenges, recent incidents, customer obligations.

- Document review: policy, responsibilities, hazard assessment, action plans, training registers, periodic checks, critical instructions.

- Field visits: sensitive workstations, machines, traffic, chemicals, non-routine work (LOTO, height, fire, confined spaces), PPE, evacuation.

- Interviews: management, managers, maintenance, HSE/HR, employee representatives, critical subcontractors.

- Hierarchical synthesis:

- Top 10 major risks (severity x frequency)

- Critical deviations (safety/compliance blockers)

- Rapid opportunities (high-impact quick wins)

Stage 2: Appointment of the MSST team and resource planning

Objective: clarify “who does what”, with the right level of expertise.

- Roles:

- Directorate: validates policy, resources and priorities.

- MSST referent (internal): steers, monitors actions, reports.

- Security specialist: methods, analyses, audits, securing critical operations.

- Occupational physician/health protection: exposure, monitoring, RPS/TMS.

- Field liaison (team leaders, maintenance): day-to-day deployment.

- RACI (responsible, support, consulted, informed) by site: machines, LOTO, chemistry, height, fire/evacuation, RPS/TMS, training.

- Planning: 30-60-90 day milestones, budget, dedicated time, monthly reporting.

Stage 3: 90-day action plan (quick wins + medium-term projects)

Objective: to quickly secure what matters, without putting off the fundamental issues.

Week 1-2: express security

- Simple material corrections (protectors, signage, storage, lanes).

- Upgrading displays: emergencies, evacuation, PPE, critical instructions.

- Launch of overdue periodic checks (fire extinguishers, lifting, electrical).

Week 3-6: critical operations under control

- Consignment/LOTO deployed: procedures, individual padlocks, “zero energy” test, training.

- Machine safety: risk analyses, compliance plans, emergency stop tests.

- Chemistry: inventory, SDS, storage, ventilation, operating procedures.

- Height/fire/confined spaces: work permits, checklists, emergency plan.

Week 7-12: system that holds up

- Hazard assessment reviewed and traceable (method, prioritisation, evidence).

- Targeted training programme (first aid, fire/evacuation, LOTO, height, chemistry, screen workstations).

- OHS dashboard and steering routine (monthly 30 min meeting, indicators, arbitrations).

- Internal audit to monitor and close critical actions.

Deliverables: 90-day plan, action log (status/due dates/responsible parties), minutes of updates and tests, signed checklists.

Stage 4: Training, documentation, measurement and continuous improvement

Training

- Skills matrix by position, retraining intervals, traceability of clearances.

- First aid modules: BLS-AED-SRC, fire/evacuation, LOTO, working at height, chemistry, ergonomics.

Document

- Clear operating procedures (normal, non-routine operations).

- Single MSST file per site: hazard assessment, action plans, records, audit minutes, photo/video evidence.

Measure

- Simple, useful KPIs: accidents/near accidents, action closure rate, training coverage, audits completed, critical gaps open/closed.

- Quarterly management meetings: decisions, priorities, resources, communication.

Improve.

- REX (feedback) loop after incident/inspection.

- Efficiency tests: observation at the workstation, quizzes, 5-minute flash audits.

- Updated for each change (machine, process, product, organisation).

Deliverables: skills matrix, annual training plan, updated MSST file, monthly dashboard, review minutes.

Taking action: MSST support and targeted training

- Express diagnostic (2-3 hours) to objectify your priorities and calibrate the 90-day plan.

- MSST support: making critical operations safe, bringing machines/LOTO into compliance, structuring documentation, coaching managers.

- Targeted training: BLS-AED-SRC first aid, fire/evacuation, machine safety, working at height, chemistry, ergonomics and RPS/TMS.

- Sustainability: quarterly internal audit, steering rituals, continuous improvement.

Frequently asked questions about workplace safety in Switzerland (FAQ)

Suva or cantonal inspectorate: who checks my service company?

In most cases, a service company is subject to cantonal inspection. If, however, you carry out particularly hazardous operations in-house (electrical maintenance, work at height, work on machinery, explosive atmospheres, etc.), you can expect requirements that are in line with Suva standards. For multi-site or multi-trade operations, skills may vary depending on the dominant activity at each site.

Does CFST Directive 6508 apply to micro-businesses?

Yes, according to the principle of proportionality. Even a very small organisation must be able to demonstrate that it has identified its hazards, defined measures and secured the necessary skills. Specialists must be called in as soon as the hazards or complexity exceed in-house skills.

Can I outsource the entire MSST function?

No. You can appoint external specialists and an occupational physician, but the employer remains fully responsible. Appoint an internal contact person, keep control of prioritisation and monitor actions over time.

What risks does an SME run in the event of non-compliance during an inspection?

You will receive written requirements with deadlines and follow-up checks. In the event of serious and immediate danger, an operation or a machine may be stopped until corrective action is taken. Indirect costs (downtime, process redesign, emergency training) are common if prevention is not structured.

How long should MSST evidence and inspection reports be kept?

Adopt a clear archiving policy: keep your documents for as long as necessary to demonstrate risk control and traceability of decisions, at least over several inspection cycles and for the lifetime of the installations concerned. Align this policy with your internal assurance, quality and compliance requirements.

How can I find out quickly whether my company is covered by Suva or the cantonal inspectorate?

List your actual activities (production, worksites, maintenance, specialist subcontracting) and your critical operations. If you operate machinery, work at height, work with dangerous energy or handle hazardous substances, you probably have technical requirements similar to those of Suva. Conversely, a core tertiary activity with no high-risk processes generally falls within the remit of the cantonal inspectorate.

How do you prepare for a test in less than two weeks?

- Put together your MSST file: hazard assessment, action plan, training/habilitation registers, periodic checks, critical instructions.

- Do a targeted tour: machines, LOTO, height, chemistry, evacuation, PPE, displays.

- Correct visible quick wins: guards, signage, traffic lane, fire extinguishers, evacuation plans.

- Schedule essential retraining (fire/evacuation, first aid, LOTO) and document it.

- Hold a preparation point with management and the MSST referent to validate priorities and messages.