What are the different types of fire and how do you extinguish them?”

24/06/2025

Swiss occupational safety players: Suva, SECO, CFST/EKAS and cantonal inspectorates

30/08/2025Table of contents

Introduction: Why CFST 6508 compliance is a must

The CFST 6508 directive requires many companies to set up a structured and verifiable safety system. This legal text obliges employers to guarantee the health and safety of their employees via a documented, compliant and proactive organisation. As soon as a company employs 10 people or has one or more specific hazards (chemical, mechanical, thermal, etc.), it is obliged to comply with this requirement.

Complying with the CFST 6508 is not just about avoiding a penalty or meeting an administrative obligation. Above all, it’s about effectively preventing occupational risks, reinforcing the safety culture and protecting people and activities. The benefits are tangible: fewer incidents, a better working environment, a stronger reputation and the anticipation of inspections.

The directive is based on a precise frame of reference: the MSST system, which is based on 10 key elements. These pillars make it possible to organise, plan, involve and correct all safety actions in a structured manner. This guide explains, step by step, how to understand and apply these requirements in your company. You’ll find concrete examples, practical advice and a tried-and-tested method for achieving sustainable, effective compliance.

Understanding CFST directive 6508 and the MSST system

Origin and scope of the directive

Directive CFST 6508, issued by the Federal Coordination Commission for Occupational Safety, is one of the fundamental texts of Swiss law on the prevention of occupational risks. It requires companies to incorporate into their operations a structured occupational health and safety management system (MSST) based on the principle of proportionality: the resources committed must be appropriate to the size of the company and the hazards involved.

In practical terms, the directive makes operational a proactive and traceable approach that covers the entire prevention cycle:

- Assess risks in a structured way (hazardous situations, non-routine operations, subcontractors).

- Plan and document technical, organisational and human measures with responsible parties and deadlines.

- Train and empower exposed employees (including retraining).

- Pilot and measure via indicators, internal audits and management reviews.

- Prove control through an up-to-date MSST file (assessments, action plans, registers, procedures).

- Continuously improve thanks to feedback and checks by the authorities.

The directive also provides for calling in specialists (occupational physician and safety specialist) when the hazards are specific or when in-house skills are not sufficient (new production line, complex processes, repeated events, multi-site, etc.). It applies to all employers, regardless of sector or size, and links up with the enforcement provided in Switzerland by Suva, the cantonal inspectorates and the SECO.

The aim is twofold: to protect workers’ health and to ensure compliance with legal obligations. Based on the principles of the directive, the MSST system installs a safety culture that goes beyond technical gestures to become a strategic lever for performance (reduced absenteeism, operational reliability, attractiveness and partner confidence).

To situate your company in the Swiss ecosystem and prepare for your inspections, consult our 2025 guide to occupational safety players in Switzerland (Suva, SECO, CFST/EKAS, cantonal inspectorates).

Which companies are concerned

The directive applies to all companies operating in Switzerland that meet one of the following criteria:

- they have 10 or more employees,

- they are exposed to one or more particular hazards identified in Annex 1 of the Directive (chemicals, explosion, radiation, machinery, etc.),

- they have several sites or are organised in a complex way.

This means that many SMEs in French-speaking Switzerland are affected, including those in industry, construction, logistics, health, education and public administration. As soon as one of these conditions is met, the company must set up a compliant and documented system, known as an MSST system.

Focus on solutions: inter-company, individual, subsidiary model

There are three ways of meeting this obligation:

- The inter-company solution: often supported by a trade association or branch, this offers a shared framework recognised by the CFST. It includes shared tools (manuals, checklists, procedures) and enables SMEs to benefit from streamlined support.

- The individual solution: the company builds its own bespoke MSST system, with the help of qualified external specialists (safety engineer, hygienist, occupational physician). This solution offers greater flexibility but requires more resources.

- The subsidiary model: intended for small structures subject to particular hazards but without organisational complexity. It enables requirements to be met in a simplified way, provided that each measure is documented and the appropriateness of the actions taken is proven.

Each solution involves a specific level of responsibility, but they all have one thing in common: they structure the safety organisation around the 10 elements of the MSST system.

The 10 elements of the MSST system: practical implementation

Element 1 – Defining guiding principles and safety objectives

It all starts with a clear line: the guiding principles in terms of safety must be formulated by management and made official. These principles express the company’s commitment to health and safety at work. They serve as a foundation for future concrete actions and help to guide all decisions.

Safety objectives must be measurable, realistic and regularly reviewed. They may involve reducing the number of incidents, increasing the training attendance rate or dealing with 100% of identified non-compliances. The key is to make these objectives part of a continuous improvement process and to share them with the teams. A good safety action plan always starts with a strong intention, expressed in writing.

Element 2 – Organising safety at work

Safety can only be effective if responsibilities are clear. This requires the employer to define precisely who does what in terms of safety within the company. The key people need to be identified: the OHS coordinator, the team leader, the training manager, or approved external contributors.

Each person involved must know his or her role, the limits of his or her action and the skills required. This organisation can be formalised in a safety organisation chart or a table of responsibilities. At the same time, it is essential to put in place a delegation and monitoring procedure to ensure that everyone is acting within their remit, in line with the objectives set.

Good safety organisation also relies on the fluidity of exchanges: information feedback circuits must be known, simple and fast to ensure maximum responsiveness in the event of an incident.

Element 3 – Identifying and assessing occupational risks

This stage is the cornerstone of any preventive approach. It involves identifying actual or potential hazards in the working environment, by analysing workstations, equipment, substances used, traffic flows and repetitive movements.

A common method is to use a risk rating matrix, cross-referencing the probability of occurrence with the potential severity of the consequences. Each risk is then classified by level of priority. This assessment must be documented, regularly updated and included in a risk register.

The analysis must be participative: involving employees helps to identify hazards that are often invisible on paper but very real in the field. It must also take account of past events (near misses, incidents, non-compliances) to anticipate critical situations. The more rigorous the assessment, the more relevant and effective the resulting measures will be.

Element 4 – Planning safety measures

Once the risks have been identified, it is essential to plan concrete preventive measures. For each risk, this involves defining the actions to be taken, who is responsible for them, the resources required and the timescales for implementation.

The measures may be technical (insulation, ventilation, signalling), organisational (changes to procedures, maintenance planning) or human (training, awareness-raising, support). The important thing is to prioritise actions according to the criticality of the risks.

One tool often used is the safety action plan, in the form of a monitoring table. It enables all measures to be centralised and traced, and ensures that nothing goes unanswered. Planning is a key stage in transforming risk assessment into an operational strategy.

Element 5 – Implementing the measures defined

Planning is not enough: the measures decided upon must be effectively applied in the field. This requires rigorous coordination between the various departments involved (technical, HR, logistics, production, etc.).

Each action must be accompanied by appropriate documentation: safety instructions, operating procedures, workstation sheets, emergency protocols. It is also necessary to ensure that the equipment or devices provided (PPE, fire extinguishers, signs) are available and used.

The success of this stage depends on the ability to integrate the measures into the company’s existing processes, without unnecessarily adding to work routines. Internal inspection visits are used to check that the measures are being applied correctly, and to make adjustments quickly if necessary. Safety must become a daily reflex, visible in actions and in the organisation.

Element 6 – Training and informing employees

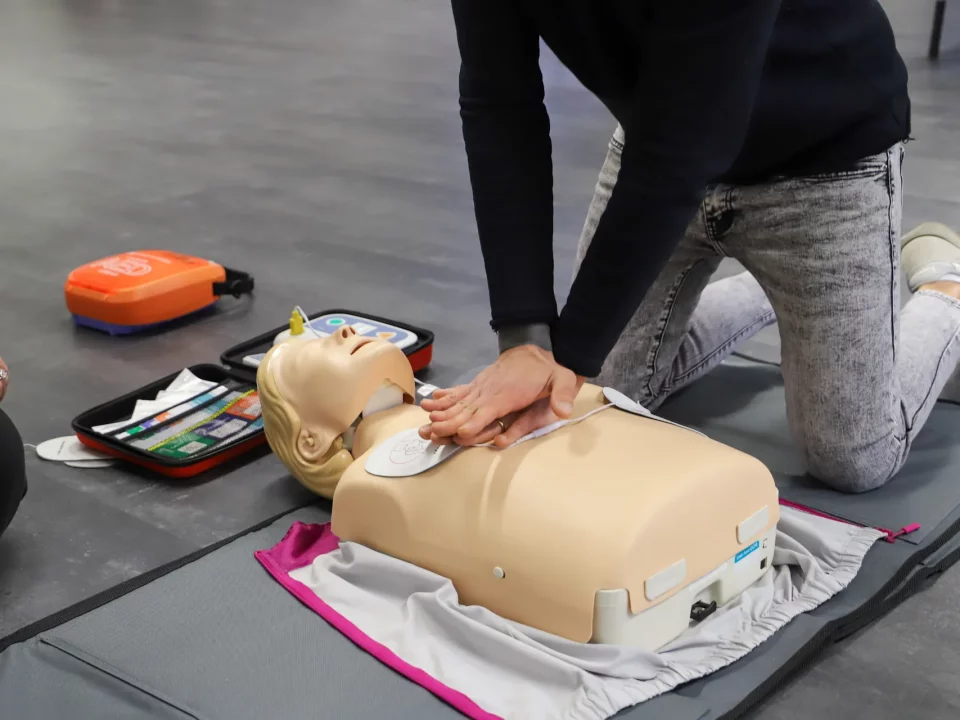

Safety at work depends on appropriate behaviour. To achieve this, employees must receive regular training, depending on the risks associated with their activity and their responsibilities. This may involve general training (first aid, fire, evacuation) or specific training (dangerous products, gestures and postures, working at height).

These training courses must be planned, followed and validated by attestations or certificates, particularly when required by law. Information, for its part, involves visual aids, safety briefings, regular reminders and clear displays.

The CFST 6508 directive stresses the need to make employees active participants in their own safety. Well-designed training tailored to the field is a powerful lever for reducing risky behaviour and reinforcing collective vigilance. It is also proof of the company’s commitment to its teams.

Furthering the training of people in charge of safety, PERCO training is specially designed to ensure compliance with MSST obligations and reinforce prevention on a daily basis.

Element 7 – Documenting actions taken

Every safety action must be traceable. The directive requires rigorous documentation: decisions taken, measures applied, training followed, checks carried out, etc. The aim is to guarantee transparency and the ability to prove compliance in the event of an inspection or accident.

This documentation can take various forms: safety register, updated action plan, meeting minutes, attendance sheets, training certificates, audit reports. It must be accessible to the people concerned and kept according to a clear document management logic.

A good documentation system also makes it possible to capitalise on past experience and ensure continuity of action, even in the event of a change of personnel. When it comes to safety, what isn’t written down doesn’t exist: this is the basis of any credible organisation.

Element 8 – Involving employees in the process

The active participation of employees is a cornerstone of the MSST system. Far from being mere executors, they are the first to be affected by the risks and are often in the best position to identify situations that need improving. Their involvement enhances the relevance of actions and encourages long-term support.

This may involve setting up a safety committee, appointing OHS representatives for each sector, or organising regular opportunities for exchange (suggestion boxes, team meetings, internal surveys). It’s also a good idea to include safety in annual appraisals or daily briefings.

The directive also encourages worker consultation on prevention objectives and measures. This collaborative approach develops a genuine safety culture, based on trust, listening and shared responsibility. An involved company is a more resilient company.

Element 9 – Responding to incidents, accidents and near misses

Even with a solid prevention system, undesirable events can still occur. The company must then react quickly, in a structured and documented way. Each incident or accident must be analysed in depth to identify the causes and prevent it from happening again.

It is important to put in place an emergency management protocol: securing the premises, first aid, informing managers and recording the event. Once the situation is under control, an analysis of the causes (often in the form of a cause tree) helps to understand the human, technical and organisational factors involved.

Near misses”, which are often overlooked, are valuable indicators. They must be reported and treated with the same rigour, because they reveal potential flaws in the system. Reacting professionally and methodically means turning every event into a learning opportunity.

Element 10 – Continuous monitoring, correction and improvement

The final element of the MSST system establishes a dynamic of continuous progress. This involves regularly checking the effectiveness of the safety measures put in place, identifying any deviations and correcting what needs to be corrected. This is achieved through internal audits, field inspections, management reviews and OHS performance indicators.

Each inspection must lead to a concrete improvement plan, with corrective or preventive actions. It is also essential to monitor changes in risks, work processes, legislation and internal and external feedback.

Continuous improvement is what distinguishes passive compliance from living safety. It enables the company to remain aligned with current standards, to gain in organisational maturity and to anchor the safety culture in its DNA over the long term.

Discover how to translate the directive into an operational action plan >

Practical focus: how SafetyFirst helps you implement the MSST system

Implementing the 10 elements of the MSST system can seem complex for a company just starting out. That’s why SafetyFirst offers comprehensive, personalised support that complies with CFST Directive 6508.

It all starts with an initial audit MMST carried out by experienced specialists. This assessment enables risks to be analysed, regulatory shortcomings to be identified and a clear picture of the current situation to be drawn up. A prioritised action plan is then drawn up, with concrete recommendations for each area (organisation, training, documentation, procedures, etc.).

SafetyFirst also offers certified training, in first aid, fire, evacuation or mental health, tailored to the specific needs of each company. The sessions are interactive, field-oriented and designed to enhance the skills of all employees, from managers to operators.

Finally, support continues after implementation. The SafetyFirst team remains available to help document actions, update registers, organise internal controls or respond to an inspection by the authorities. Thanks to this tailor-made approach, more than 300 companies in Western Switzerland have already strengthened their safety and ensured their compliance.

Conclusion: Towards a sustainable culture of safety at work

Complying with CFST Directive 6508 is more than just fulfilling an obligation. It means making a strategic choice to invest in human safety, the long-term future of the company and the confidence of its teams. Thanks to a 10-stage structured approach, the MSST system provides a clear framework for organising, managing and continuously improving health and safety at work.

Each company can adapt this framework to its own reality, as long as it surrounds itself with the right tools and the right partners. SafetyFirst offers practical, proven and recognised support to transform compliance into a performance driver.

Ready to take the plunge? Take stock with an initial audit or discover our customised training courses. Together, we can build a strong, vibrant and sustainable safety culture.