Swiss occupational safety players: Suva, SECO, CFST/EKAS and cantonal inspectorates

30/08/2025

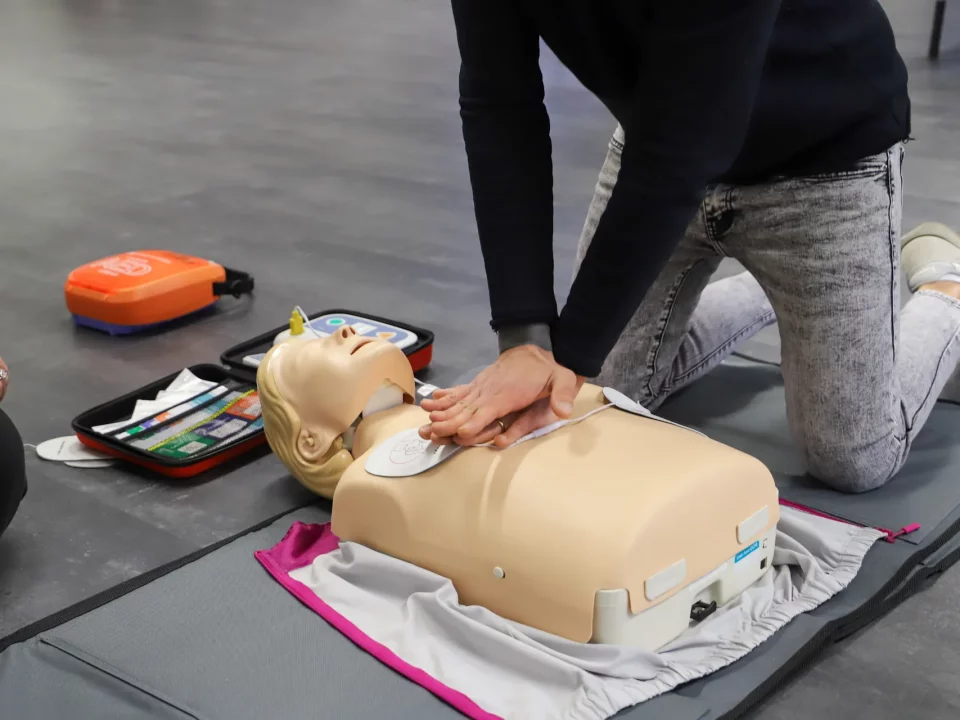

Integrating BLS-AED into OHS: how to plan training in your safety action plan

16/10/2025Table of contents

When it is compulsory to call in MSST specialists

In Switzerland, all employers are responsible for the safety and health of their employees. Directive CFST 6508 specifies that recourse to external specialists becomes obligatory when the risks exceed the company’s internal competencies.

Cases where an occupational physician is required in Switzerland

An occupational physician intervenes as soon as there are exposures that could have an impact on long-term health :

- noise or vibrations in excess of the limit values,

- handling solvents, dust, fumes or biological agents,

- jobs with atypical working hours or a high mental workload,

- frequent cases of musculoskeletal disorders (MSD) or high absenteeism.

It provides appropriate medical monitoring, advises the employer and proposes corrective measures in terms of ergonomics, organisation or personal protection.

Situations requiring a safety specialist in accordance with CFST directive 6508

The use of a safety specialist is required when the company presents major technical or organisational hazards:

- use of hazardous machinery (presses, saws, pressure equipment),

- work at height or in confined spaces,

- risk of fire, explosion (ATEX) or gas leak,

- handling hazardous chemicals,

- electrical work or maintenance operations requiring consignment (LOTO).

These specialists help to assess risks, draw up critical procedures and train staff.

Common risks in SMEs: chemicals, machinery, RPS, ergonomics

Even SMEs in the tertiary or craft sector can be affected. The most common dangers are:

- the use of chemical cleaning products without appropriate protection,

- unsecured workshop machines,

- organisational stress and psychosocial risks (PSR),

- disorders linked to workstation ergonomics.

In these cases, the support of an occupational physician or safety specialist is not just a constraint: it’s an investment to avoid accidents, occupational illnesses and costly downtime.

The role of the occupational physician in the MSST

The occupational physician occupies a central position in the MSST system. His role goes far beyond simply issuing a medical certificate: he helps to build a health prevention strategy durable at work , tailored to the company’s specific risks.

Health prevention and medical monitoring of workers

The occupational physician assesses the impact of working conditions on employee health. He or she defines preventive measures and proposes appropriate follow-up in the event of specific risks. This includes:

- periodic medical check-ups for exposed jobs;

- advice on adapting working hours, breaks and rhythms;

- support for returning to work after an accident or occupational illness.

Managing psychosocial risks (RPS) and musculoskeletal disorders (MSD)

RPS (chronic stress, burnout, burnout) and TMS (back pain, tendonitis, neck pain) are among the most common problems in Switzerland.

The occupational physician helps to :

- identify the organisational factors at risk,

- propose measures to reduce mental workload,

- raise awareness of active prevention among management and employees.

Ergonomics and improving workstations

An essential part of the occupational physician’s role is to analyse the ergonomics of workstations:

- seat adjustment, screens and computer stations,

- optimisation of repetitive movements,

- recommendations for limiting physical fatigue.

These actions help to reduce absenteeism and improve productivity.

Monitoring occupational exposure (noise, solvents, dust)

The occupational physician is also responsible for monitoring occupational exposure:

- noise and vibration ;

- solvents and fine dust ;

- fumes, gases, infectious agents ;

- radiation or toxic substances.

It defines the appropriate medical surveillance protocols, recommends collective or individual protection, and alerts management if legal limits are exceeded.

The role of the safety specialist in the MSST

The safety specialist, recognised under the CFST guideline 6508, provides essential technical expertise to prevent serious accidents and control risky situations. It acts as a complement to the occupational physician, with an approach focused on machinery, processes and working environments.

Technical analysis of machine and equipment risks

The safety specialist carries out detailed analyses of workstations and equipment:

- machine compliance (enclosures, emergency stops, collective protection),

- checking locking devices,

- study of traffic flows (pedestrians / machinery).

Its role is to anticipate potential accidents and propose concrete corrective measures.

Fire, explosion and chemical product prevention

Some activities involve specific hazards that require advanced expertise:

- fire risks associated with electrical equipment, the storage of flammable liquids or welding workshops;

- risks of explosion (ATEX) in dusty environments or when handling gases;

- management of hazardous chemicals: safety data sheets (SDS), storage, labelling, appropriate protective equipment.

The specialist defines the technical, organisational and human measures to be put in place to guarantee security.

Critical procedures: consignment (LOTO), work permits, confined spaces

In industrial or maintenance environments, certain operations require absolute rigour:

- Lockout/tagout (LOTO): securing a machine before any work is carried out.

- Work permit: for sensitive activities (welding, working at height, electricity).

- Confined spaces: planning, ventilation, atmospheric monitoring, emergency procedures.

The safety specialist develops these critical procedures, trains the teams and ensures that they are applied in the field.

Employee safety training and evacuation drills

An essential part of its role is to pass on good practice:

- targeted training (working at height, chemicals, ATEX, machinery),

- raising awareness of the correct use of PPE,

- organisation of evacuation drills and incident simulations.

These training courses reinforce the safety culture and ensure that every employee knows how to react to hazards.

How to ensure effective collaboration between experts and in-house staff

A successful MSST does not rely solely on the skills of external specialists: it must be integrated into the life of the company. The key is smooth collaboration between the occupational physician, safety specialist, management, HR and employees.

The Safety Committee’s role in the organisation

The safety committee (or SST committee) is the place where all the stakeholders meet. It should regularly bring together :

- management or its representative,

- the internal OHS manager,

- external specialists (doctor, security),

- employee representatives.

Objectives: monitor the progress of actions, share observations in the field, make rapid, documented decisions.

Role of management and HR in OSH coordination

- Management: provides strategic impetus, validates resources and ensures that prevention is integrated into the company’s priorities.

- HR: manages administrative follow-up (training register, medical visits, absence follow-up) and acts as a relay between employees and experts.

When management and HR are involved, the MSST ceases to be perceived as a constraint and becomes a management tool.

Occupational physician and safety specialist working together: a winning partnership

These two experts have complementary missions:

- the occupational physician provides the health, ergonomics, RPS and exposure vision ;

- the safety specialist provides technical expertise, procedures and training.

Working hand in hand, they :

- enhance hazard assessment (health + technical),

- coordinate action plans,

- avoid duplication or inconsistency,

- guarantee comprehensive risk cover.

Their collaboration ensures that the MSST is not a stack of isolated measures, but an integrated and coherent strategy.

How to choose your MSST experts in Switzerland

Choosing specialists is a strategic step: a competent occupational physician and an experienced safety specialist make the difference between a theoretical MSST and a truly effective system. Here are the key criteria for selecting your partners.

Check CFST 6508 certification and recognition

In Switzerland, experts must be recognised in accordance with directive CFST 6508.

- The occupational physician must be trained in occupational health, empowered to provide appropriate medical surveillance.

- The security specialist must have certification attesting to their technical and organisational skills.

Always check the titles and approvals: this is a guarantee of compliance in the event of a Suva or cantonal inspection.

Focusing on sector-specific experience

Specialists do not have the same expertise depending on their background.

- In construction, he will be able to manage the risks of height, machinery, dust and internal traffic.

- In industry, he will be familiar with chemicals, electricity, consignment (LOTO) and ATEX.

- In the tertiary sector, they will need to master RPS, ergonomics and stress management.

Choose an expert who knows your sector and your constraints on the ground.

Define a clear mission: specifications, deliverables and follow-up

Before signing, clarify the specifications:

- Precise objectives (initial audit, regular monitoring, training).

- Expected deliverables (reports, procedures, certificates).

- Frequency of interventions (one-off, annual, monthly).

- Communication methods (meetings, minutes, reporting).

A well-defined assignment avoids misunderstandings and enables the added value of the expert to be measured.

Outsourcing vs. in-house resources: which model to choose?

- Total outsourcing: practical for SMEs with no in-house skills. Advantage: cutting-edge expertise, up-to-date standards. Disadvantage: external dependency.

- Trained internal resources: helps to embed the safety culture on a daily basis. Requires specific training and regular monitoring.

- Hybrid model: often the most effective → an internal referent who works in partnership with external experts.

The important thing is not the model chosen, but that the company always has qualified and up-to-date skills to cover its risks.

Conclusion: from perceived “cost” to performance lever

Calling in an occupational physician and a safety specialist is not an unnecessary burden: it’s the surest way to turn MSST into an operational advantage. Together, they reduce accidents, limit absenteeism, secure audits and install a culture of prevention that shows up in the field – not just in the documents.

To remember:

- The occupational physician = health, ergonomics, RPS, exposure.

- The safety specialist = machinery, chemistry, fire/ATEX, LOTO, procedures.

- The pairing, supported by management and an internal referent, makes your MSST effective and provable.

Taking action

- Need a turnkey framework? Discover our MSST Concept (method, deliverables, support).

- Want a quick, objective assessment? Launch an Initial MSST Audit to prioritise the right actions.